Non-Contact Inductive Encoders in IP69K

02/13 – Turck is presenting the first non-contact and absolutely wear-free universal encoder that stays permanently sealed

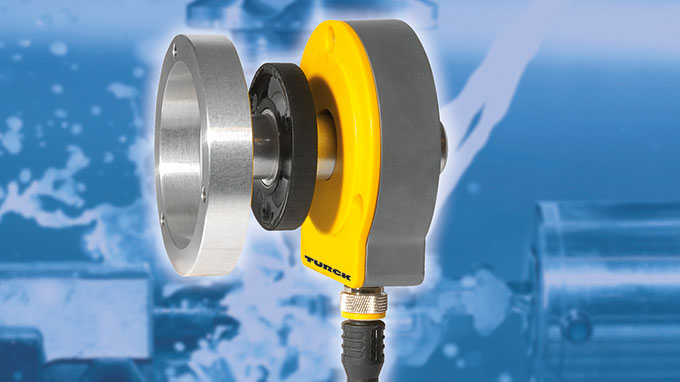

Mülheim, February 19, 2013With the RI360P-QR24, Turck is the first manufacturer to offer on the market a non-contact inductive universal encoder with high resolution, absolutely wear-free operation, which is at the same time immune to magnetic fields. The sensor and the positioning element of the encoder are fully encapsulated and therefore designed as two independent and fully sealed units that work together without contact. Any vibration or shock from the shaft is therefore not passed on to the sensor. This makes the RI360P-QR24 a superior sensor compared to both optical and magnetic encoders. Thanks to its high degree of protection to IP69K and over 18-bit resolution, machine downtimes and maintenance times resulting from encoder wear are from now on a thing of the past, even with high-precision and high-speed applications.

Turck developed a revolutionary parameterization and mounting concept for the encoder. This turns the RI360P-QR24 into a universal encoder for any standard industrial application. Users can parameterize the device either as an incremental, multi-turn or single-turn encoder. This variant allows the user to also set output signals, switch points and measuring ranges individually via IO Link. Moreover, Turck is offering a high-resolution variant with an SSI output, a Modbus and voltage/current version, as well as an encoder compliant with the e1 specification, for use on mobile machines. The mounting concept of the encoder also extends its application range: Adapter rings enable the encoder to be fitted on all standard shafts with diameters up to 20 millimeters.

With the RI360P-QR24, Turck is the first manufacturer to offer on the market a non-contact inductive universal encoder with high resolution, absolutely wear-free operation, which is at the same time immune to magnetic fields. The sensor and the positioning element of the encoder are fully encapsulated and therefore designed as two independent and fully sealed units that work together without contact. Any vibration or shock from the shaft is therefore not passed on to the sensor. This makes the RI360P-QR24 a superior sensor compared to both optical and magnetic encoders. Thanks to its high degree of protection to IP69K and over 18-bit resolution, machine downtimes and maintenance times resulting from encoder wear are from now on a thing of the past, even with high-precision and high-speed applications.

Turck developed a revolutionary parameterization and mounting concept for the encoder. This turns the RI360P-QR24 into a universal encoder for any standard industrial application. Users can parameterize the device either as an incremental, multi-turn or single-turn encoder. This variant allows the user to also set output signals, switch points and measuring ranges individually via IO-Link. Moreover, Turck is offering a high-resolution variant with an SSI output, a Modbus and voltage/current version, as well as an encoder compliant with the e1 specification, for use on mobile machines. The mounting concept of the encoder also extends its application range: Adapter rings enable the encoder to be fitted on all standard shafts with diameters up to 20 millimeters.

Stainless Steel Variant

Turck also offers its customers a robust stainless steel variant of the contactless, inductive encoder QR24. The new EQF24 variant of the wear-free encoder is suitable for use in the food industry as well as in many other applications. With the V4A stainless steel housing (1.4404) and the active surface made of PA12-GF30 plastic, the device withstands even aggressive chemicals and high pressures in the cleaning process. The new EQF24 is available with incremental output and SSI interface.

Incremental Output

The incremental variant of the QR24 completes the portfolio. Its pulse rates can be defined by the customer. The user simply sets the number of pulses per revolution between 1 and 5,000 via the Pactware parameterization software. As before, the encoder can also be taught to one of the nine most common preset pulse rates using the Turck teach adapter.