Monitoring Cooling and Lubrication Circuits in CNC Machines

Turck's FS121 offers flexible and cost-efficient monitoring for CNC machines, even in areas that are difficult to access

Coolants and lubricants used in CNC machines prevent cutting tools and workpieces from overheating, flush out the machining chips and provide lubrication to achieve a smooth surface finish on the workpiece.

Prevention of tool and workpiece damage

Failure of the coolant and lubricant supply can cause considerable damage to workpieces or cutting tools. By using a flow sensor, this can be prevented by ensuring a continuous supply of coolant and lubricant and automatically stopping the machining process in the event of interruptions. However, the ideal mounting location for the flow sensor in the enclosed CNC machine is difficult to access.

Your Benefits

- High flexibility: supports different measuring probes and media (liquids and gases)

- Space-saving installation: cabinet-free installation thanks to protection class IP67, compact design

- Easy handling: alphanumeric plain text display and Quick Teach function

- Cost reduction: one IO-Link processing unit for many remote sensors

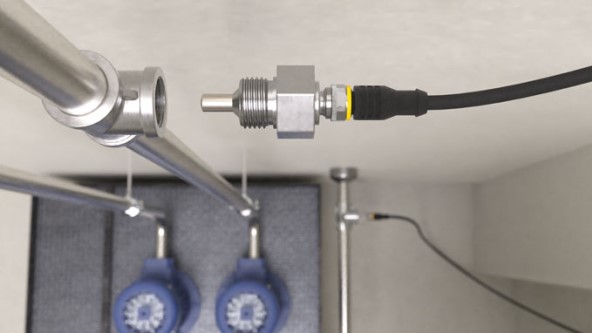

Help is provided by a solution that not only allows the sensor to be installed, but also initial settings and adjustments to be made during operation, despite the restricted installation conditions: Turck's FS121-2UPN8-H1141, a processing unit for remote flow sensors, enables comprehensive and flexible monitoring of the coolant and lubricant supply even under the most difficult installation conditions. It enables flexible monitoring using various remote probes and can be easily integrated into decentralized systems.

Simple setup and operation

Thanks to the remote mounting option, the FS121 can be installed in optimum positions within the enclosed CNC machine without any loss in functionality. This ensures that the flow monitoring works effectively even in the confined environment of the system. Equipped with a 12-segment alphanumeric display, the processing unit enables intuitive navigation through the menus, making initial setup and adjustments during operation much easier.

Flexibility and adaptability

The FS121 can be used with various flow sensors that have been specially developed for use with oil and emulsions. Flow sensors made of special materials are also used to meet specific requirements in CNC machines.

Seamless integration into automation system

Thanks to the IO-Link Smart Sensor profile and IP67 protection, the sensor solution can be seamlessly integrated into the existing automation environment. This enables efficient provision and management of process and diagnostic data, which improves the reliability and transparency of the production process.

The FS121 offers a robust and flexible solution for continuous monitoring of the CNC machine, which significantly increases the safety and efficiency of the production process.

-turck-image.jpg)

-turck-image.jpg)

-turck-thumbnail.jpg)

-turck-thumbnail.jpg)