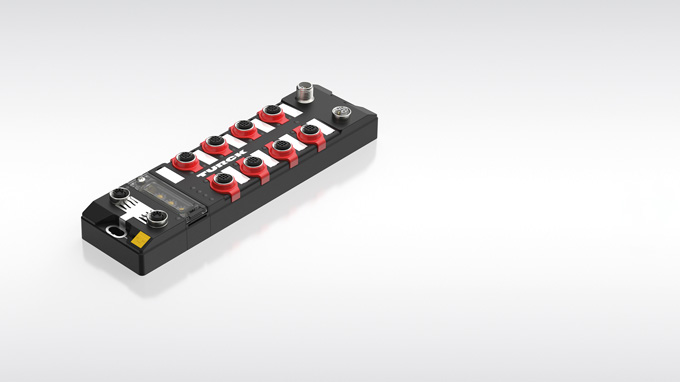

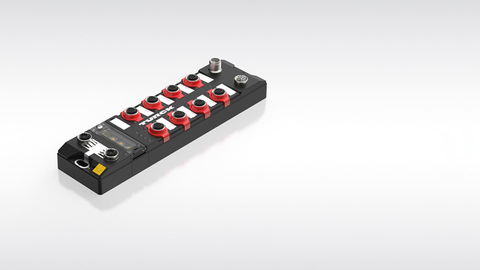

Turck's TBEN-LL-4FDI-4FDX safety block I/O modules enable flexible and decentralized safety control without the need for central control cabinets

Safety Multiprotocol Modules with Safe Link

16/24 – Turck's safety network platform offers cost-efficient and flexible safety solutions for small to medium-sized plants – right through to ATEX Zone 2/22

Turck is presenting a networked machine safety solution that is specially tailored to the requirements of small to medium-sized plants: The combination of the Turck Safe Link safety protocol with the TBEN-LL-4FDI-4FDX safety block I/O modules allows the creation of flexible and cost-efficient safety control with a decentralized installation. The multiprotocol modules support Ethernet/IP, Profinet and Modbus TCP and use the Turck Safe-Link protocol for safety cross communication. The safety logic is implemented directly in the modules with safety inputs and outputs.

The networked modules produce a modular and scalable safety architecture that considerably reduces cabling effort and installation time. Up to 31 modules can be networked in an application, and each module provides 127 diagnostic bytes for monitoring and fast troubleshooting. Each module provides two bytes for safety input and output data as well as an additional two bytes for non-safety input and output bits for fieldbus communication with a non-safety PLC. The decentralized installation of the modules reduces the need for central control cabinets and simplifies both the maintenance as well as the expansion of the system.

Approval for ATEX Zone 2/22 makes the modules suitable for use in hazardous areas. This means that safety signals can even be reliably transferred in harsh environments. The safe block I/O modules TBEN-LL-4FDI-4FDX will be available in the first quarter of 2025.