Your Global Automation Partner

DIGITAL CONVEYOR LINES

Modularization and Digitization Increase Flexibility, Scalability and Availability of Your Conveyor Technology

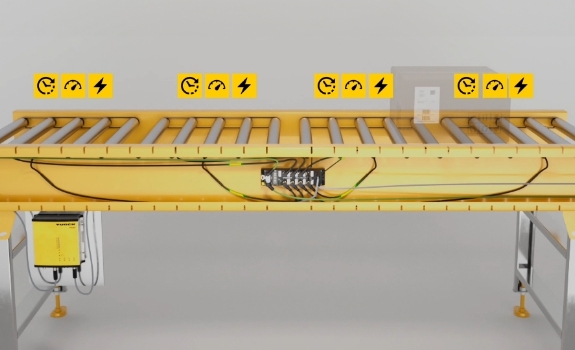

The best way to meet the rapidly changing requirements of your customers is to use modular, flexibly scalable conveyor lines. If these are then also to be highly available and work without back pressure, there is no way around an efficient digitization strategy. The trend is moving away from centrally controlled and driven lines to decentralized control modules and roller drives directly on site.

Future-oriented conveyor technology can be modularized with:

- Block I/O modules with integrated MDR control via CAN

- 24 and 48 volt IP67 power supplies with M12 power

- Ethernet-Switches in IP20 oder IP67

- IP67 safety controls

The Future of Conveyor Technology — Modular and Decentralized!

Webinar: Digital Conveyor Technology – Flexible, Scalable, Available!

Fast-changing customer requirements, more complex supply chains and increasing pressure for efficiency are key challenges in intralogistics. In our webinar recording, you can learn how modularization and digitization of your conveyor technology overcome these hurdles. Discover how smart automation technology optimizes your processes, increases flexibility, improves scalability, and maximizes availability.

How to Increase the Flexibility, Scalability and Availability of Your Conveyor Technology

Modularization and digitization

- Modular conveyor lines with decentralized control concepts without control cabinets ensure easy scalability, short cycle times and higher plant availability.

- End-to-end digitalization of the conveyors enables the acquisition of status data, access to sensors/actuators and flexible control, for example for zero pressure accumulation conveying.

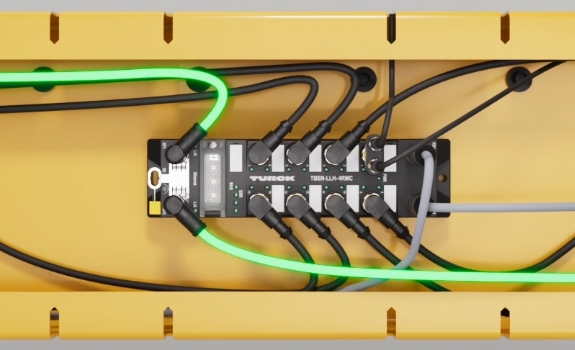

Roller motor controller TBEN-LL-4RMC

- Block I/O module with multiprotocol Ethernet controls four CAN roller motors locally and simultaneously integrates sensors and actuators via universal DXP ports.

- IP67 power supplies with 24 and 48 volts, M12 power supply and snap-on connectors facilitate the design and construction of autonomous conveyor technology modules.

Condition monitoring for preventive maintenance

- Condition monitoring data such as current consumption, speed or operating hours are acquired on the motor and evaluated in our own systems or in TAS Cloud.

- Continuous process data monitoring and optimization allows predictive maintenance and guarantees high reliability, lower costs, maximum availability.

IIoT Service Platform Turck Automation Suite (TAS)

- TAS simplifies update management of motors and commissioning of Turck devices in Industrial Ethernet networks including ARGEE, BEEP, Codesys and IO-Link applications.

- TAS Cloud provides continuous monitoring, cloud-based data storage and processing, and programming and tracking of individual maintenance plans.

E-Book: Digital Conveyor Lines

With These Products, You Digitize Your Conveyor Line

Safety block I/O modules

Safe block I/O modules in IP67 control safety-related applications directly on the conveyor line via Profisafe or CIP Safety — decentralized and with short reaction times.

Turnkey RFID tunnel/gates

Turnkey UHF RFID tunnels for conveyor lines and gates for incoming/outgoing goods are ready for immediate use and can be flexibly integrated – precise tracking in intralogistics.

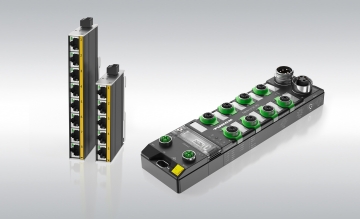

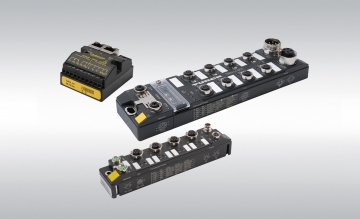

Reliable Ethernet switches

Reliable Ethernet switches — whether IP20 or IP67, managed or unmanaged — in ring topology are the basis for high-performance and secure networks and modular conveyor routes.

Sophisticated connectivity

Sophisticated connection technology, especially with quick-connect M12, reduces wiring costs and facilitates modularization.

Smart block I/O modules

Smart block I/O modules with ARGEE logic take over decentralized control tasks and TBEN-LL-4RMC modules control CAN roller motors.

Decentralized power supplies

Decentralized switched-mode power supplies secure the power supply in modular systems from -25 to +70 °C — fail-safe thanks to no-load, overload and short-circuit protection.

Versatile photoelectric sensors

Versatile photoelectric sensors in numerous variants and designs detect all forms of goods and containers without contact with particularly fast response times.

Variable signal lights

Variable signal lights and optical displays with LED technology indicate process and machine status clearly visible and language-neutral — even acoustically.

Comprehensive safety portfolio

A comprehensive safety portfolio, from safety light curtains to safety controllers, enables tailor-made solutions for maximum machine safety at full performance.

Ask an Expert

Would you like to learn more about how you can benefit from the digitization of your conveyor lines? Then simply use our contact form. I will be happy to advise you.

Our expert for digital conveyor lines