Your Global Automation Partner

Visit us at the HOME OF AUTOMATION!

At the leading industry highlight for smart and digital automation, TURCK will be showcasing innovative solutions for a networked, efficient, and sustainable industry at booth 250 in hall 7. Experience how you can master your challenges in production and logistics with intelligent automation solutions. We’ll demonstrate how Industrial AI, decentralized automation, sensor-to-cloud concepts, and our offering for Digital Conveyor Lines enable error-free, transparent, and energy-optimized processes. Plus, our smart software solutions unlock the full potential of your systems. Present your project to us in Nuremberg and we will make your challenge our own.

Top Trade Fair Topics at a Glance

Digital Conveyor Lines: Modular, Transparent, Efficient

A special highlight at the TURCK booth is the topic of digital conveyor lines. Our conveyor line application will show you how smart digitalization and automation can take your intralogistics to a whole new level. The digitized conveyor lines with TURCK's block I/O control modules for roller motors and other decentralized IP67 components, from 48V power supplies and switches to safety modules, reduce data traffic, cycle times, and the risk of failure – flexibly scalable, highly available, energy-efficient, and set up in no time without back pressure.

More Efficiency, Less Effort: AI-Powered Automation with TAS & TIV

TAS: TURCK Automation Suite

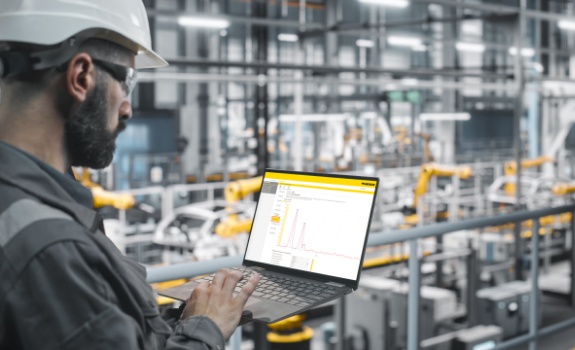

With the IIoT and service platform TAS, TURCK not only simplifies the management and configuration of TURCK devices in Ethernet networks, but also status monitoring, plant management, and remote maintenance for machines and plants via TAS Cloud. With functions such as network scanning, batch configuration, and firmware updates, TAS Desktop offers a central platform for commissioning, maintenance, and condition monitoring. TAS Cloud complements this with, among other things, an intelligent maintenance manager that allows users to create maintenance plans for machines using a modular principle, as well as smart AI services such as anomaly detection, etc.

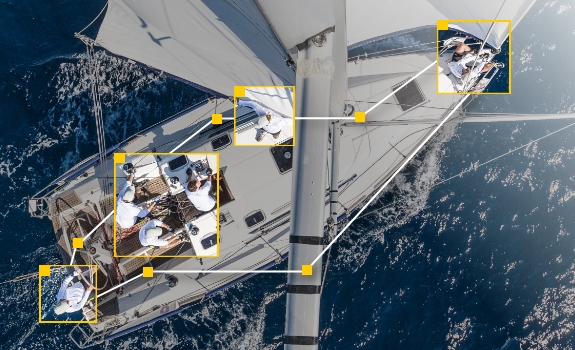

TIV: AI Camera for Smart Inspection

With the new TIV AI camera, TURCK brings artificial intelligence directly into production. The self-learning camera processes image data locally and in real time, simplifying anomaly detection and difference checking. This makes the TURCK Intelligent Vision Camera ideal for applications such as quality or completeness checks, object classification, or process monitoring. With its intuitive user interface and easy integration into existing systems, the TIV is a milestone for industrial AI. Integration into TAS also enables seamless connection with other automation solutions from TURCK ensuring consistent data flow and efficient system interaction.

TURCK Vilant Systems (TVS) implements RFID turnkey solutions from the data carrier to software integration. The TVS software is central to the success of a track-and-trace solution. Find out in Nuremberg how the Visibility Manger and other TVS software bring transparency to your logistics.

Decentralized Automation

Decentralized automation reduces machine costs and time to market, speeds up commissioning, and increases availability. With IP67 components, you can move I/O and control from the control cabinet directly to the field. This results in flexible, modular machine concepts – a clear advantage in times of dynamic markets, growing uncertainty and increasing demands.

Sensor to Cloud

How do you extract the information that is really relevant to you from the Internet of Things – without overloading networks or revealing protected content? TURCK's answer: with networked, smart sensors, efficient edge controllers, and simple cloud solutions. Benefit from digital value creation between the shop floor and the cloud – with TURCK's integrated IIoT architecture from a single source.

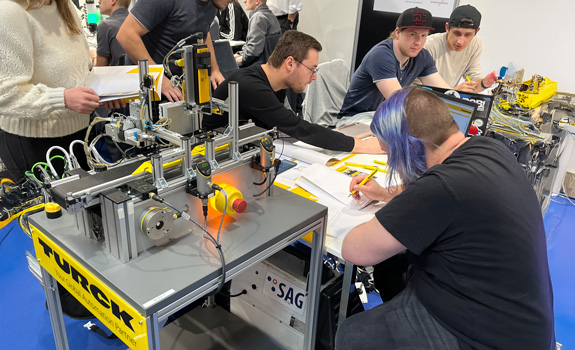

Young Talents @ TURCK

Attention young talents: At the SPS Makeathon, young professionals work in interdisciplinary teams to develop creative solutions for real-world automation tasks—supported by partners such as TURCK. In addition, we invite you to the Job Rally on Young Talents Day on November 27: Discuss career opportunities, collect stamps, and take part in the competition!

Your Global Automation Partner Live in Nuremberg

Take the opportunity and talk to TURCK experts about your project at the SPS. We are looking forward to meeting you!