Your Global Automation Partner

IIoT Connects Worlds: Seamless Data Communication Between Sensor and Cloud

Digitization is entering more and more industrial sectors. Technologies such as IO-Link, RFID and Ethernet increase the amount of data from the machine environment many times over, and cloud services enable mobile access worldwide. But: How do you extract the information that is really relevant to you from the Internet of Things – without overloading networks or revealing protected content? Turck's answer: With networked sensors, efficient edge controllers and simple cloud solutions – in short, with decentralized automation.

Big Data is filtered specifically to Smart Data via decentralized preprocessing. In this way, you can use parameters, process values or status messages in a targeted and safe manner for the purpose of your application – for example, for condition monitoring. The end-to-end networking of sensors with higher-level IT systems such as clouds, however, opens up many other possibilities. For example, bidirectional communication allows remote access to devices and plant segments, worthwhile for deployments such as global servicing. In addition, high data availability paves the way for completely new processes in production, logistics and supply chain management.

Discover Turck's future-proof IIoT architecture, from rugged sensors, powerful I/O devices and edge controllers to customized cloud applications.

Putting Wheels in Motion: Grasp the Benefits Available

Efficient data transfer

- Decentralized on-site preprocessing in the Edge enables fast, latency-free responses to events

- Multiprotocol Ethernet and edge controller technology reduce hardware and network capacity requirements

- Focusing on relevant data increases transparency in higher-level systems

Future-proof system

- Open system landscape allows modular design and integration of third-party devices and various clouds

- Condition data as the basis for predictive maintenance ensure high availability in the long term

- Integrated networking enables access to machines and controls down to the individual device

High protection against cyber crime

- Edge computing reduces data flow to the cloud – leaving sensitive data in the OT network

- Kolibri protocol guarantees encrypted and lean communication to the cloud

- Integrated firewalls and security functions protect against manipulation

Global one-stop shop

- Complete solution from a single source: From sensors, connection, I/O and network technology to edge controllers and cloud system

- Sharing with only one competent contact person saves time and guarantees device compatibility

- International production and distribution network provides worldwide on-site support and services

Webinar: Remote Maintenance with Cloud Solutions

In the Video: Data Transfer From the Sensor to the Cloud – and Back Again

Follow the continuous communication path between machine level and IT. See where Turck's edge controllers with smart preprocessing ensure efficient data communication

Whitepaper: Bidirectional Communication Opportunities in Industrial Cloud Applications

Deepen your knowledge of communication paths from sensor/actuator level to the cloud. What potential do hardware and software solutions offer both for automation practice and for completely new business models? The free whitepaper has details

Smart Data Suppliers with Advanced Functions

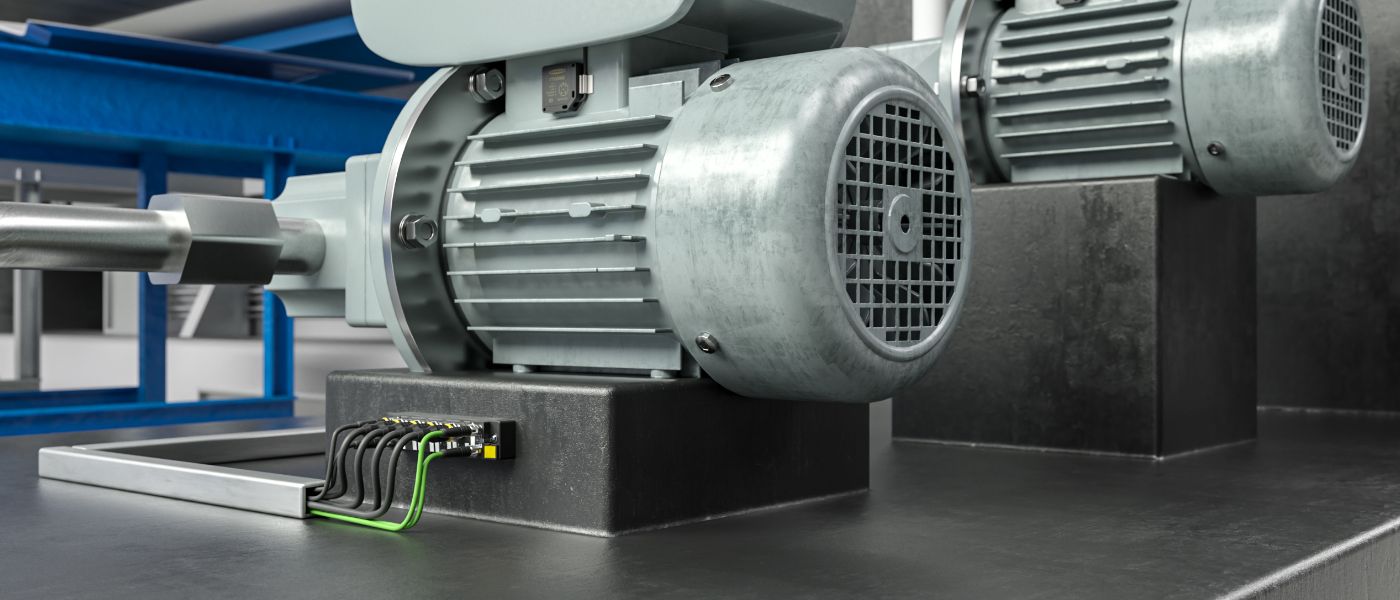

Sensors detect fluids, measure pathways or distances, and detect a wide variety of objects. In short: They generate valuable data that can be used today specifically for machine processes. Take advantage of advanced device functions to keep track e.g. of vibrations or temperature for status monitoring, with just one sensor. Turck's IM18 cabinet controller has even three sensors on board and transmits measured values to the IT environment via Ethernet.

With IO-Link, sensors become active system participants. Thanks to digital communication, users not only obtain better information from sensors and actuators, but can also make it more easily available for applications in MES, ERP and cloud systems. Reading out internal memory, recording states, performing diagnostics or identifying and locating components – such tasks can be solved easily with IO-Link.

Creating Room to Maneuver: Fields of Application of Sensor-to-Cloud Solutions

Awaken Ideas: End-to-end Data Streams in Practice

In industrial environments, IIoT applications are no longer a vision of the future. Discover new possibilities with digital communication "to the last meter"

Find the Right Hardware and Software Solutions

Sensors

Smart sensor solutions from Turck provide data for almost all areas of industrial automation. Benefit from an extensive IO-Link portfolio that ensures communication "to the last meter", enables rapid commissioning and simplifies condition monitoring.

Edge Controllers with CODESYS

CODESYS simplifies decentralized data preprocessing. It allows you to define what information is to be transferred, and when and where. With Turck's compact I/O modules and controllers in IP67, you can bring logic directly to the machine.

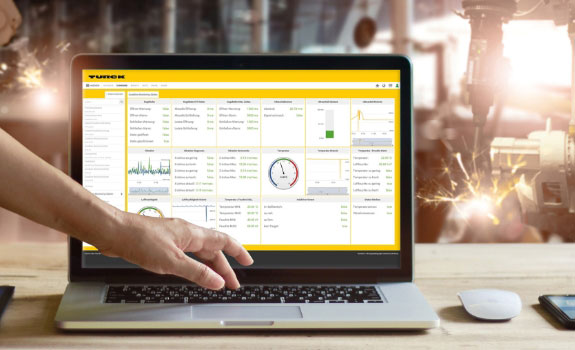

Turck Cloud Solutions

Optimized for industrial use, the Turck cloud solution offers application-specific services for machine and systems engineers. Alternatively, data can be transferred to other clouds such as MS Azure, Alibaba, AWS, or hosted on-premise at your site. Learn more about flexible monitoring and edge controllers with encrypted communication.

Clear to Lift off? Then Tell Us About Your Project...

Our experts in end-to-end sensor-to-cloud communication are looking forward to your inquiry!